The next stage in the bender’s restoration is to make a new ring for the handle. This part presents a few challenges for me: First the part is close to the capacity of the lathe and I don’t have a chuck large enough to hold it. Fortunately I do have a faceplate large enough to hold it, but only if I add mounting holes which I will then need to plug. Second because the inside of the ring provides a bearing surface for the needle rollers, I’ll need to provide a very good surface finish.

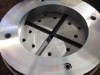

I started with a piece of 1″ thick plate with a 5″ hole burned by the steel supplier. Next I rough-cut the perimeter on the bandsaw and then moved it to the rotary table on the mill to drill the mounting holes and clean up the flame-cut hole. That done, I mounted it on the faceplate and faced both sides before turning the outside and inside.

A bearing surface ought to be hardened and ground but the original ring did not appear to have been hardened, so I will follow that lead and skip hardening the replacement. I would however like to provide a better surface than I’ve been able to achieve with my current skills and tooling which then provides an opportunity to investigate yet another old tool. Some time back I got a Dumore #44 tool post grinder at a school auction but have not had cause to use it. The motor bearings are in bad shape but the spindle appears to be okay, so I’ll start with replacement of its motor bearings…

It occurs to me that time spent in a workshop is a bit like traversing a fractal curve: regardless of where you are on the journey of discovery, there is an ever expanding level of detail yet to be explored. In this case I started out exploring the creative possibilities of bending rod, part of which exposed challenges with my bender, which then lead to a lucky find of another style of bender, its restoration, and on to a tool post grinder, which now requires making a face spanner wrench to remove the motor’s end caps… Old iron disease and life-long learning: paths leading ever onward.